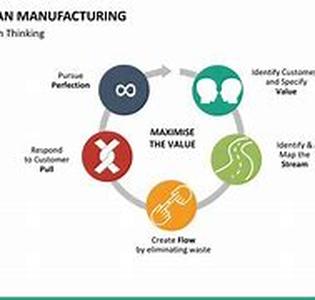

Implementing The Lean Manufacturing StrategyBefore We Discuss How To Implement The Much Discussed Corporate Planning Strategy Known As Lean Manufacturing, Let Us First Define What It Is.Lean Manufacturing Is A Combination Of Approaches That, When Put Together, Aims To Eliminate The All The Common Practices That Are Seen As Wholly Unnecessary And Time-consuming. Such Are Called Wastes, Like Overproduction, Long Waiting Times, Transportation And Constant Motion, Which Not Only Eat Up Precious Time But Are Also A Drag On Resources, Energy And Expenses. Simply Put, Implementing Lean Manufacturing Has The Reduction Of Costs In Mind. And This Is Done, Ironically, By First Making Sacrifices On The Strategies That Have Been In Effect In Many Companies For Decades Now. Sound Like A Dangerous Plan? Some Companies Believe It Is, But When You Really Look At Its Long Term Benefits, You Will Find That Implementing Lean Manufacturing Will Bring Greater Value To Your Company Than The Processes That Have Already Been Ingrained. After All, Change Is Often For The Better. You Just Have To Open Your Eyes And Welcome It.Implementing The Lean Manufacturing Program Is Best For Companies That Have Output And Production As Their Primary Source Of Revenue. Such Companies Place A Prime On Maximizing All Their Human And Tool Resources In Order To Achieve Their Target Output Levels Without Having To Spend Too Much.This Is Where The Principles Of Lean Manufacturing Are Most Helpful.Prevailing Economic Conditions Often Leave Companies Scampering For Clients. Growing Competition Are Forcing Producers To Lower Their Charges Just To Be Able To Get Ahead, That's Why Such Firms Are Looking For Novel Ways To Lower Their Production Costs And Increase Turnaround Times. When Firms Need To Boost Efficiencies And Generate Revenue, Lean Manufacturing Is Often What Is Implemented. Implementing Lean Manufacturing Techniques Has Been Found Effective In The Survival And Success Of A Company Or An Organization. This Is Because Of The 'elimination Of Seven Wastes' Philosophy This Program Espouses.For A Shorter Version, What Lean Manufacturing Aims To Teach Is The On Time, At The Right Time And At The Right Quantity Approach To Production. For Instance, Producing Too Much That What Is Needed Is Often Detrimental To A Company. Sure, It Shows That Targets Have Not Only Been Achieved, But Grossly Surpassed. But This Does Not Always Entail Success.Implementing Lean Manufacturing Systems Means That There Should No Waste. That Is, No Unnecessary Stockpiles That Could Just Sit At Warehouses And Left To Rot. If You Produce More Than Intended, This Is What Will Likely Happen To Your Inventory.You'll Take Up Warehouse Space And See The Products Get Worn By Time. If You're Lucky, You'll Be Able To Dispose Of The Excesses, But They Won't Likely Be Sold At Their Original Price Because, Well, They'll Be Considered Old Stocks Or Overruns. Before You Plan To Implement Lean Manufacturing Strategies, It's Best To Be Prepared. Critics Are Not Kidding When They Say That Lean Manufacturing Is Somewhat Tricky, Because The Preliminary Preparations Can, Indeed, Deter You From Pushing Through. However, Consider The Long Term Gains You Will Obtain From This System. If You List Pros And Cons, You Will Find That The Benefits Will Significantly Outweigh The Tedious Preparations And Planning By A Long Shot. Once You've Laid Down What Needs To Be Changed And What Needs To Be Eliminated, Implementing Should Be A Piece Of Cake. Good Luck!